Metallized BOPP Films Market 2025 Targets 1.8x Growth by 2034 with 9 to 30 Micron Film Dominating Over 65 Percent of Global Consumption

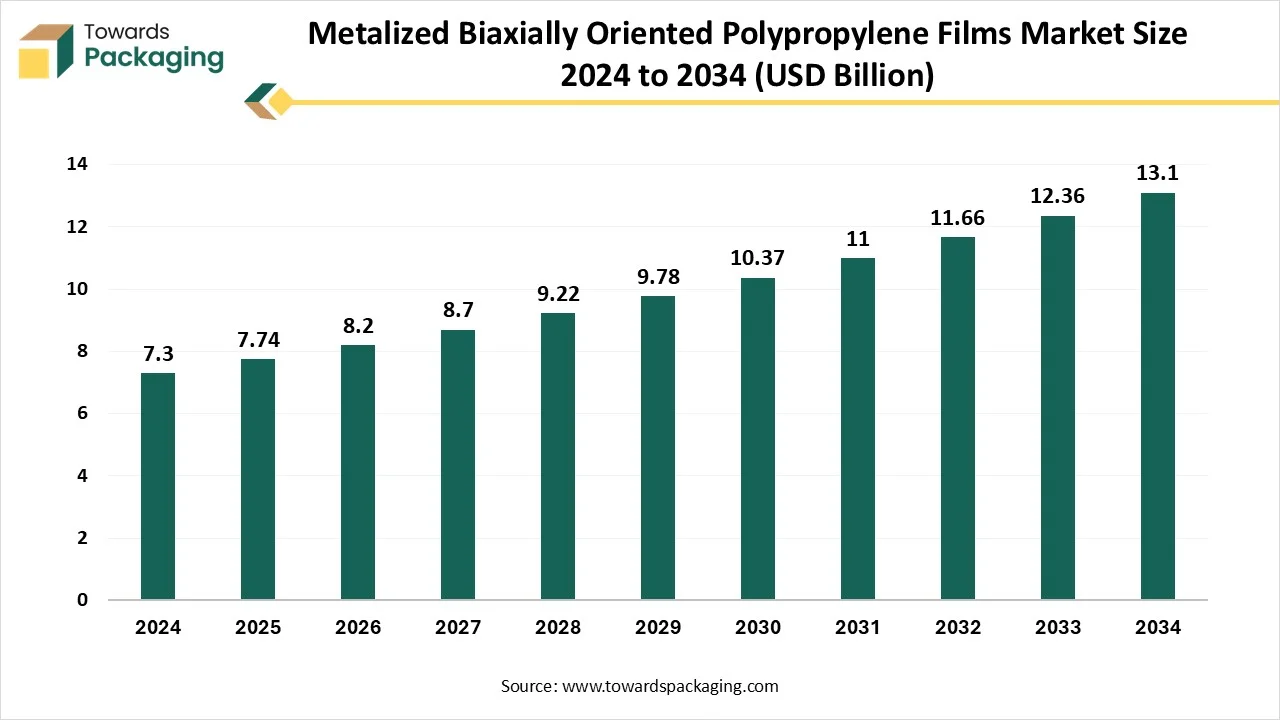

According to a recent analysis by Towards Packaging, the global metalized biaxially oriented polypropylene (BOPP) films market is projected to expand from USD 7.3 billion in 2024 to USD 13.1 billion by 2034, recording a CAGR of 6.05% between 2024 and 2034.

Ottawa, July 31, 2025 (GLOBE NEWSWIRE) -- The global metalized biaxially oriented polypropylene (BOPP) films market size reached approximately USD 7.74 billion in 2025, with projections suggesting it will climb to USD 13.1 billion in 2034, according to a report from Towards Packaging, a sister firm of Precedence Research.

Get All the Details in Our Solutions – Access Report Sample: https://www.towardspackaging.com/download-sample/5636

Metallized biaxially oriented polypropylene (BOPP) is experiencing robust momentum, primarily propelled by expanding demand in the packaging sector, especially food, beverage, personal care, pharmaceuticals, and labeling applications, where enhanced barrier, mechanical, and aesthetic properties are vital. Asia-Pacific leads current market share and growth, with India and China fueling increasing adoption.

Europe is emerging as a fast‑growing region, supported by stringent recyclability regulations and sustainable packaging initiatives. Market participants include vertically integrated firms such as Cosmo Films Ltd., Jindal Poly Films, Taghleef Industries, and Uflex, which leverage technological advancement and operational efficiency to maintain dominance. Innovation focuses on films with superior optical clarity, barrier performance, and improved recyclability, addressing regulatory shifts and consumer preference for eco‑friendly materials.

What Is Meant by Metallized Biaxially Oriented Polypropylene Film?

Metallized biaxially oriented polypropylene film is a specialized plastic film that has been stretched in both the machine and transverse directions to enhance its strength, clarity, and barrier properties. This biaxial orientation improves its tensile strength and resistance to moisture and gas. The film is then coated with a thin layer of metal, typically aluminum, through a vacuum metallization process.

This metallization significantly enhances its barrier properties against light, oxygen, and moisture, making it ideal for packaging applications. The resulting film is lightweight, cost-effective, and visually appealing with a shiny, reflective finish, commonly used in snack food packaging, labels, and gift wraps.

If there is anything you'd like to ask, feel free to get in touch with us @ sales@towardspackaging.com

What Are the Latest Trends in the Metallized Biaxially Oriented Polypropylene Films Market?

- Enhanced barrier and thinner films: Manufacturers are producing ultra‑thin metallized BOPP (9–30 µm and even sub‑9 µm) with improved oxygen, moisture, and UV resistance, extending shelf life while reducing weight.

- Sustainability and recyclability focus: Mono‑material PP laminates, solvent‑free inks, biodegradable coatings, and aluminum‑reduction are being developed to meet circular economy and regulatory demands.

- Digital and high‑impact aesthetics: Integration of digital-print‑ready coatings, holographic, matte‑metal, and anti‑counterfeiting finishes for premium branding and customization.

- AI‑driven manufacturing: Predictive maintenance, defect detection, and real‑time quality control systems are optimizing metallization processes and lowering costs.

-

New industrial applications: Growth in electronics insulation, anti‑static films, pharmaceutical packaging, and nutraceutical pouches is fueling demand for high‑barrier and tailored BOPP solutions.

What is the Potential Growth Rate of the Metalized Biaxially Oriented Polypropylene Films Market?

- Boom in the packaged food and beverage industry: The increasing consumption of ready-to-eat snacks, confectioneries, and beverages has boosted the demand for durable, lightweight, and attractive packaging materials.

- Rapid growth in e-commerce and retail sectors: Online and organized retail channels require robust and visually appealing packaging, driving demand for metallized BOPP films with aesthetic finishes and durability.

- Rising use in labels and decorative packaging: The film’s glossy appearance and printability make it ideal for labels, gift wraps, and decorative applications, further expanding its end-use segments.

- Technological advancements in film production: Innovations such as thinner films, better metallization techniques, and improved surface coatings enhance performance, reduce material use, and increase product appeal.

- Increased pharmaceutical and personal care usage: These industries use metallized BOPP for protective, tamper-evident packaging solutions, further driving market growth.

- Regulatory push for shelf-life extension and food safety: Global regulations requiring extended product shelf life and improved food safety encourage the use of high-barrier films like metallized BOPP.

Limitations & Challenges in Metalized Biaxially Oriented Polypropylene Films Market

Limited Recyclability in Mixed Laminates & Environmental Regulations and Plastic Bans

The key players operating in the market are facing issues like stringent regulatory laws and limited recyclability, which are estimated to limit the market growth. While BOPP is recyclable, metallized variants, especially when used in multi-layer laminates with other plastics, pose challenges in recycling, limiting their acceptance in highly sustainability-focused regions. Polypropylene, obtained from crude oil, experiences volatile pricing. Increasing raw material costs can raise production expenses and squeeze manufacturers' profit margins.

Heightened awareness of plastic pollution and tighter regulations, especially in Europe and parts of North America, are driving manufacturers to adopt biodegradable or paper-based substitutes in the metalized biaxially oriented polypropylene films market. Alternatives such as aluminum foil, paper laminates, biodegradable films, and polyethylene variants increasingly compete, especially in markets emphasizing sustainability or barrier qualities.

More Insights of Towards Packaging:

- Chemical Repackaging Market - The chemical repackaging market is booming, poised for a revenue surge into the hundreds of millions from 2025 to 2034.

- Polyhydroxyalkanoates Films Market - The global polyhydroxyalkanoates films market is predicted to expand from USD 15.91 billion in 2025 to USD 36.76 billion by 2034, growing at a CAGR of 9.75%.

- Cling Films Market - The global cling films market is forecast to grow from USD 13.06 billion in 2025 to USD 19.41 billion by 2034, driven by a CAGR of 12.5% from 2025 to 2034.

- Sustainable Films for Packaging Market - The global sustainable films for packaging market is projected to reach USD 392.7 billion by 2034, expanding from USD 191.04 billion in 2025.

- UV Resistant Films Market - The UV-resistant films market is set to grow from USD 3.66 billion in 2025 to USD 6.37 billion by 2034, with an expected CAGR of 6.43% over the forecast period from 2025 to 2034.

- Specialty Films Market - The global specialty films market is expected to increase from USD 22.13 billion in 2025 to USD 27.16 billion by 2034, growing at a CAGR of 2.33%.

- BOPP Films Market - The global BOPP films market is set to grow from USD 31.51 billion in 2025 to USD 50.16 billion by 2034, with an expected CAGR of 5.34% over the forecast period from 2025 to 2034.

- Agricultural Films Market - The agricultural films market is expected to increase from USD 12.52 billion in 2025 to USD 21.02 billion by 2034, growing at a CAGR of 5.94%.

- Protective Films Market - The protective films market is forecast to grow from USD 21.11 billion in 2025 to USD 36.16 billion by 2034, driven by a CAGR of 6.27% from 2025 to 2034.

- Shrink Packaging Market - The shrink packaging market is anticipated to grow from USD 12.51 billion in 2025 to USD 21.68 billion by 2034, with a compound annual growth rate (CAGR) of 6.30%.

Regional Analysis:

Who is the Leader in the Metalized Biaxially Oriented Polypropylene Films Market?

Asia‑Pacific commands a dominant position in the metalized biaxially oriented polypropylene films market thanks to rapid industrialization, urbanization, and rising consumer incomes across China, India, and Southeast Asia. A booming food, beverage, personal care, and pharmaceutical industry fuels continuous demand for high-barrier and flexible packaging. The region also benefits from well-developed manufacturing infrastructure with low-cost polymer extrusion and high-volume vacuum metallization capacity, enabling competitive production and export advantages.

The expanding electronics sector and government support for related R&D and electric mobility initiatives underpin high demand for metallized films for insulation and capacitor applications. Growth is further accelerated by favourable regulatory frameworks that support sustainable packaging innovation and local investments in production expansion.

China Market Trends

China is the largest producer and consumer of metallized BOPP films in the region. The country has a strong foothold in the packaging and electronics industries, driving massive demand for high-barrier, lightweight films. China's cost-effective manufacturing, government-backed industrial infrastructure, and export-driven packaging sector significantly contribute to regional dominance.

India Market Trends

India is a rapidly growing market due to increasing consumption of packaged food, snacks, personal care, and pharmaceutical products. Rising middle-class income, urbanization, and the growing organized retail sector support strong demand for flexible packaging solutions. The Make-in-India initiative has further encouraged local BOPP film production.

Japan Market Trends

Japan’s metallized BOPP film demand is driven by its advanced electronics and automotive sectors. The country uses these films extensively in capacitors, EMI shielding, and high-end packaging. Japan also leads in innovation, developing ultra-thin, high-performance BOPP films for precision applications.

South Korea Market Trends

South Korea contributes significantly to the regional market, with its strong semiconductor and electronic component manufacturing industry. Metallized BOPP films are widely used in insulation and high-frequency electronic applications. The country also focuses on eco-friendly packaging materials.

How is the Opportunistic Rise of Europe in Metalized Biaxially Oriented Polypropylene Films Market?

Europe is expected to grow at the fastest rate in the metalized biaxially oriented polypropylene films market for several key reasons. First, stringent environmental regulations, including the EU’s Circular Economy Action Plan and REACH compliance, have prompted a shift toward recyclable, lightweight packaging materials, accelerating the adoption of mono‑material metallized BOPP films.

Strong demand across premium packaging, personal care, and food & beverage industries in countries like Germany, France, Italy, and the UK is boosting the consumption of high-barrier films with excellent aesthetic appeal and extended shelf life. Finally, advanced manufacturing infrastructure and investment in innovation, such as expansion of multi‑layer co‑extrusion capacity and development of ultra-thin, sustainable BOPP films, position Europe as a leader in next-generation packaging technology.

Germany Market Trends

Germany leads the European market due to its strong industrial base in food processing, pharmaceuticals, automotive, and electronics. The country emphasizes sustainable and high-performance packaging, with many manufacturers investing in recyclable and mono-material metallized BOPP films. Germany also hosts some of the region’s top packaging machinery and materials producers.

France Market Trends

France shows rising demand driven by its luxury goods, cosmetics, and gourmet food industries, where metallized BOPP films are valued for their aesthetic appeal, printability, and barrier performance. Government regulations supporting eco-friendly packaging also push the adoption of recyclable film solutions.

Italy Market Trends

Italy plays a crucial role in its large flexible packaging and converting sector. It is a significant exporter of packaged foods and personal care products, contributing to high domestic demand for metallized BOPP films. Local converters focus on premium and visually appealing film products.

U.K. Market Trends

The UK is seeing robust demand due to its e-commerce expansion, organized retail, and preference for sustainable packaging materials. British packaging companies are increasingly adopting recyclable metallized BOPP films to align with environmental policies such as the Plastic Packaging Tax.

Spain Market Trends

Spain’s growing agriculture and processed food sectors require durable, high-barrier packaging for exports. This, along with increasing investment in packaging innovation, supports its demand for metallized BOPP films in both food and industrial applications.

Poland and Eastern Europe Market Trends

Countries like Poland, Hungary, and the Czech Republic are becoming manufacturing hubs for Western European brands due to lower labor costs and rising local demand. These regions are witnessing increasing investments in film extrusion and metallization facilities, fueling market growth.

How Big is the Success of the North American Metalized Biaxially Oriented Polypropylene Films Market?

North America’s metalized biaxially oriented polypropylene films market is growing notably due to a mix of sustainability focus, strong end‑user demand, innovation, and supply chain shifts. In the U.S. and Canada, rising consumer awareness and strict environmental regulations, such as extended producer responsibility and carbon-footprint reduction, have increased the adoption of recyclable, lightweight BOPP films with lower plastic consumption. Packaging demand remains robust, especially for food, beverages, personal care, and pharmaceuticals, where high-barrier and aesthetic packaging solutions are required.

Technological advancements, including metallization, co‑extrusion, multi-layer coating, and mono-material formats, are enabling customized performance and sustainability compliance. Meanwhile, rapid growth in e-commerce and demand for convenient, durable packaging heightens the need for reliable BOPP films. Infrastructure incentives under U.S. legislation like the Inflation Reduction Act are also fueling growth in specialty electrical-grade BOPP for insulation and capacitor applications, tying into renewable energy and EV manufacturing support.

How Crucial is the Role of Latin America in the Metalized Biaxially Oriented Polypropylene Films Market?

Latin America is experiencing limited growth in the metalized biaxially oriented polypropylene films market due to several restraining factors. One major challenge is the lack of advanced manufacturing infrastructure and limited access to high-end film metallization technologies, which restricts local production capabilities.

Additionally, economic instability and fluctuating raw material prices in countries like Brazil and Argentina hinder consistent investment in the packaging and industrial sectors. Environmental regulations and recycling systems are still underdeveloped, limiting the adoption of recyclable packaging materials.

How does the Middle East and Africa lead the Metalized Biaxially Oriented Polypropylene Films Market?

The Middle East and Africa (MEA) presents moderate but growing opportunities for the metalized biaxially oriented polypropylene films market. Increasing urbanization, expanding retail networks, and rising consumption of packaged food and personal care products are creating new avenues for flexible packaging demand. Countries like the United Arab Emirates, Saudi Arabia, and South Africa are investing in the packaging and FMCG sectors, which supports growth in metallized BOPP films usage.

There is growing awareness around the benefits of high-barrier, lightweight packaging solutions, especially in hot climates where moisture and UV resistance are critical. However, market penetration is still limited due to infrastructural and technological gaps. With ongoing industrial development and foreign investment in local manufacturing, MEA offers long-term potential, particularly as sustainability initiatives begin to take hold.

Join now to access the latest packaging in industry segmentation insights with our Annual Membership: https://www.towardspackaging.com/get-an-annual-membership

Segment Outlook

Application Insights

The packaging segment dominates the market due to its exceptional combination of functional and aesthetic benefits. These films offer excellent barrier properties against moisture, oxygen, and UV rays, making them ideal for preserving the freshness and shelf life of packaged products. Their lightweight and cost-effective nature, compared to alternatives like aluminum foil, makes them an economical choice for manufacturers.

Additionally, their shiny, reflective surface enhances the visual appeal of packaging, helping brands attract consumer attention. Metallized BOPP films are also highly versatile, used across food, beverages, personal care, pharmaceuticals, and other sectors. They allow for high-quality printing and labeling, supporting branding and promotional needs.

As demand for convenience and packaged foods increases, the need for durable and long-lasting packaging materials grows. Moreover, advancements in recyclable mono-material film structures make them more environmentally friendly, aligning with global sustainability trends. The growth of e-commerce and organized retail further fuels their widespread adoption in packaging applications.

The electronics and insulation segment is emerging as the fastest‑growing application within the metalized biaxially oriented polypropylene films market. This growth is primarily driven by its strong performance as a dielectric in high‑performance capacitors, offering high voltage resistance, low dissipation, and self‑healing properties essential for modern electronic circuits.

As consumer electronics, EVs, and renewable energy systems expand rapidly, demand for compact, high‑dielectric, thermally stable films continues to surge, supporting reliable capacitor performance and EMI shielding in sensitive devices. Additionally, metallized BOPP films provide moisture resistance, thermal stability, and static control (surface resistivity <10¹² Ω/sq), making them ideal for protecting electronics during transit and operation, especially in humid or high‑frequency environments.

Elevate your packaging strategy with Towards Packaging. Enhance efficiency and achieve superior results - schedule a call today: https://www.towardspackaging.com/schedule-meeting

Recent Breakthroughs in the Global Market:

- In May 2025, JPFL Films is increasing its capacity to produce BOPP films in Nashik, Maharashtra, with the anticipated commissioning of a new line in October 2026 and March 2025, as stated by Polymerupdate. This addition is a component of a more substantial investment of Rs 700 crore, the packman said. The updated line will increase their current production capacity by 60,000 tons annually.

- In May 2025, Jindal Films announced the completion of a new metallizer installation in its Brindisi plant in Italy. The addition of this metallizer increases JFE's metallisation capacity, allowing the company to meet the growing demand for recyclable Barrier BOPP and BOPE. With this new development, JFE will continue to expand its wide range of high-barrier metallized films, specifically extending the ground-breaking Alox-Lyte and ultra-high-barrier products, and expanding the selection of metallized Ethy-Lyte films.

- In May 2025, Innovia Films, a leading materials science company that converts BOPP films, introduced new enhanced vacuum-metallizing capabilities to its proprietary film-coating line at its Zacapú plant in Mexico in Q3 2025.

Metalized Biaxially Oriented Polypropylene Films Market Key Players

- Cosmo Films Ltd

- Taghleef Industries Group

- Jindal Poly Films Limited

- POLIBAK PLASTIC

- Political SA

- SIBUR

- Uflex Limited

Metalized Biaxially Oriented Polypropylene Films Market Segments

By Application

- Packaging

- Laminations, Graphics, Labels and Tags

- Electronics and Insulations

- Others

By Region

- North America

- U.S.

- Canada

- Europe

- Germany

- UK

- France

- Italy

- Spain

- Sweden

- Denmark

- Norway

- Asia Pacific

- China

- Japan

- India

- South Korea

- Thailand

- Latin America

- Brazil

- Mexico

- Argentina

- Middle East and Africa (MEA)

- South Africa

- UAE

- Saudi Arabia

- Kuwait

Invest in Premium Global Insights @ https://www.towardspackaging.com/price/5636

If you have any questions, please feel free to contact us at sales@towardspackaging.com

About Us

Towards Packaging is a leading global consulting firm specializing in providing comprehensive and strategic research solutions. With a highly skilled and experienced consultant team, we offer a wide range of services designed to empower businesses with valuable insights and actionable recommendations. We stay abreast of the latest industry trends and emerging markets to provide our clients with an unrivalled understanding of their respective sectors. We adhere to rigorous research methodologies, combining primary and secondary research to ensure accuracy and reliability. Our data-driven approach and advanced analytics enable us to unearth actionable insights and make informed recommendations. We are committed to delivering excellence in all our endeavours. Our dedication to quality and continuous improvement has earned us the trust and loyalty of clients worldwide.

Our Trusted Data Partners:

Precedence Research | Statifacts |Towards Automotive | Towards Healthcare | Towards Food and beverages | Towards Chemical and Materials | Towards Consumer Goods | Towards Dental | Towards EV Solutions | Nova One Advisor | Healthcare Web Wire | Packaging Web Wire | Automotive Web Wire

For Latest Update Follow Us: https://www.linkedin.com/company/towards-packaging/

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.